I've got two rows with 4 - 1000 watt lights in each row (total of 8kw). Room will be sealed and I will be using 8 Cool Sun reflectors with the 6" flanges.

I have two 8" Can Fans that I will be using with these lights so the duct will have to be reduced to 6" somewhere along the line.

Here's my question...

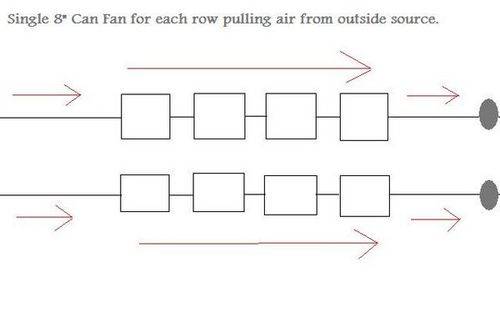

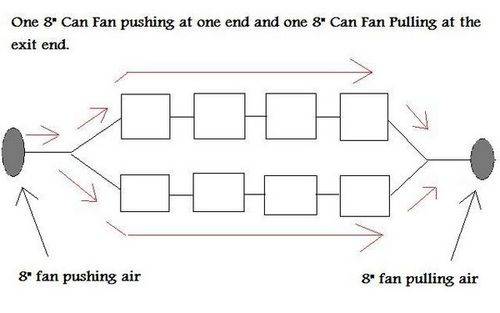

Should I run one fan per row of lights (pulling air) or should I bring in the 6" duct, push air with one fan then split / tee off this duct for both rows and then tee back to one 6" duct with another fan pulling air at the other end? Which configuration would be more efficient?

This may not make sense so I've included pictures.

Thanks guys.

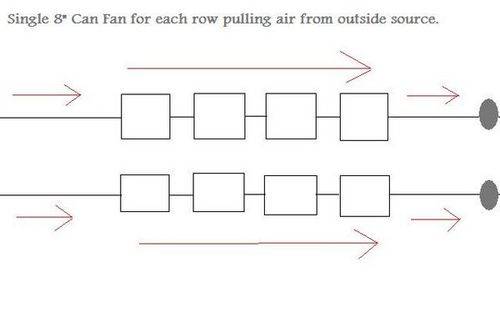

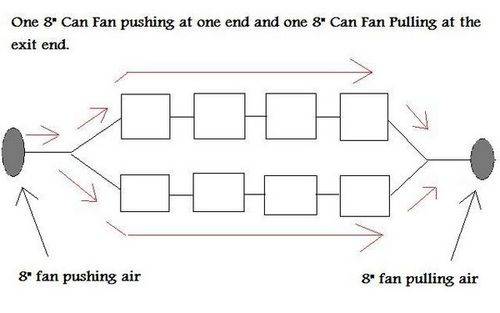

I have two 8" Can Fans that I will be using with these lights so the duct will have to be reduced to 6" somewhere along the line.

Here's my question...

Should I run one fan per row of lights (pulling air) or should I bring in the 6" duct, push air with one fan then split / tee off this duct for both rows and then tee back to one 6" duct with another fan pulling air at the other end? Which configuration would be more efficient?

This may not make sense so I've included pictures.

Thanks guys.

Last edited: