E

Elcap

Ok, I've been looking at Phason and Quantem speed controllers with idle settings.

The problem is, I don't want only a temp based controller, I can even do without the temp control. I want to be able to run at a user-set idle speed during lights off and full blast (or temp controlled) during lights on.

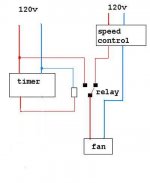

Seems I could build something using a SPDT relay and a std "dial a temp" solid state type speed controller...but I'm just not quite seeing it. Can't figure out how to wire it all. Thinking something like this:

outlet plug->DialATemp->bare wires

/ \

power->SPDT relay ==>receptacle->fan

\ bare wires---------------------->/

The idea being that the SPDT relay would switch between the dial a temp side and a "normal" full power side, both feeding a single plug/receptacle, based on my lights on/off timer. That would effectively give me an user setable lights-off idle speed.

Input?

Already have a dial a temp, and noticed that in all the speed controllers I've seen there are none with a specific night idle. There are some with day/night temp settings, and with idles but nothing quite does what I want.

The problem is, I don't want only a temp based controller, I can even do without the temp control. I want to be able to run at a user-set idle speed during lights off and full blast (or temp controlled) during lights on.

Seems I could build something using a SPDT relay and a std "dial a temp" solid state type speed controller...but I'm just not quite seeing it. Can't figure out how to wire it all. Thinking something like this:

outlet plug->DialATemp->bare wires

/ \

power->SPDT relay ==>receptacle->fan

\ bare wires---------------------->/

The idea being that the SPDT relay would switch between the dial a temp side and a "normal" full power side, both feeding a single plug/receptacle, based on my lights on/off timer. That would effectively give me an user setable lights-off idle speed.

Input?

Already have a dial a temp, and noticed that in all the speed controllers I've seen there are none with a specific night idle. There are some with day/night temp settings, and with idles but nothing quite does what I want.