green54321

Member

Hi all.

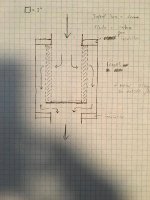

This is the basic design I'm thinking of.

-Planning to vent two 3'x3' flower spaces into it (315 watts each).

-1/4" plywood for the box.

-Metal brackets to attach the sides of the box and then glue the bejesus out of them to keep it air tight

-Want to keep the outlet side unglued so I can remove it to put in fresh carbon as needed

Couple q's:

-Would bumping the outlet up to 8" be sensible?

-How long should I make it to manage two 3'x3' spaces?

-How thick should the layer of carbon be?

-Does this seem like a good price for carbon? (in the US)

https://www.thatpetplace.com/filter-carbon-pellets-52lb

Any other suggestions?

This is the basic design I'm thinking of.

-Planning to vent two 3'x3' flower spaces into it (315 watts each).

-1/4" plywood for the box.

-Metal brackets to attach the sides of the box and then glue the bejesus out of them to keep it air tight

-Want to keep the outlet side unglued so I can remove it to put in fresh carbon as needed

Couple q's:

-Would bumping the outlet up to 8" be sensible?

-How long should I make it to manage two 3'x3' spaces?

-How thick should the layer of carbon be?

-Does this seem like a good price for carbon? (in the US)

https://www.thatpetplace.com/filter-carbon-pellets-52lb

Any other suggestions?