I made this carbon scrubber to be used with a 6” Vivosun duct booster type axial fan rated at 240cfm, dialed down on a speed controller. It could be made almost any size or shape to fit bigger or smaller fans I imagine. It’s very simple and basic with a few cool features.

I started by measuring how much room I had length wise in the top of my cabinet inline with the fan, I had plenty of room to make the filter around 19 1/4” long. Which was the full length of the metal screen I had cannibalized from a regular 6” can filter. Of course if you don’t have old filters laying around for the metal screen and fine fiberglass mesh you can use things like 1/4” hardware mesh from Lowe’s or Home Depot and panty hose or fiberglass window screen.

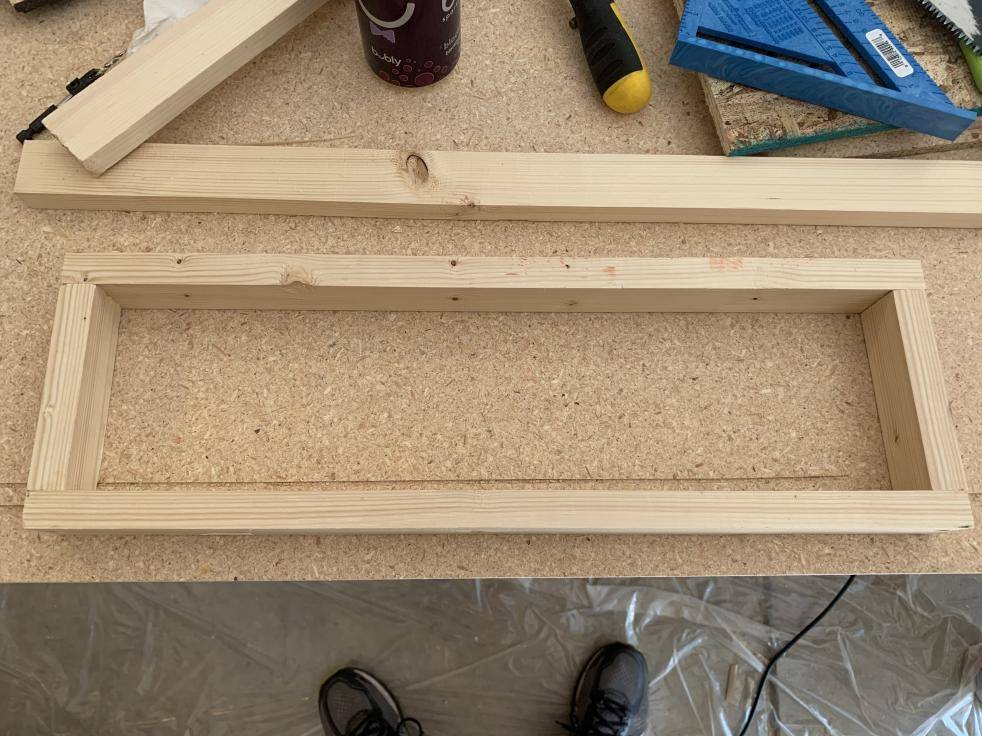

First make the frame for filter part, I used 1x2 boards, screws and wood glue.

When you have that basic frame you can measure for some wood pieces to cut to build the box that the filter will sit in. I used scrap 2/3” particle board that I had laying around from building the cabinet the filter is going in. 4x8 sheets of this particle board only costs about $10-11. It shouldn’t be hard to find scrap wood or free cheap beat up furniture locally you could cut apart if you’re really on a budget.

Cut the top and sides of the filter box long enough so that one side of the filter frame is flush with the ends, and the other side is short enough for a piece of 1x2 or similar board that will used to secure the duct to. The flush end will be capped off and the end with the price of wood will be open and connect to duct from the fan. Also make sure that the top of the filter box as well

As the “end cap piece” is cut to a width that will have the box sitting over the frame with just the slightest bit of wiggle room.

Here’s that end capped and piece of 1x2 on the open end.

Another view of where we’re at so far.

I started by measuring how much room I had length wise in the top of my cabinet inline with the fan, I had plenty of room to make the filter around 19 1/4” long. Which was the full length of the metal screen I had cannibalized from a regular 6” can filter. Of course if you don’t have old filters laying around for the metal screen and fine fiberglass mesh you can use things like 1/4” hardware mesh from Lowe’s or Home Depot and panty hose or fiberglass window screen.

First make the frame for filter part, I used 1x2 boards, screws and wood glue.

When you have that basic frame you can measure for some wood pieces to cut to build the box that the filter will sit in. I used scrap 2/3” particle board that I had laying around from building the cabinet the filter is going in. 4x8 sheets of this particle board only costs about $10-11. It shouldn’t be hard to find scrap wood or free cheap beat up furniture locally you could cut apart if you’re really on a budget.

Cut the top and sides of the filter box long enough so that one side of the filter frame is flush with the ends, and the other side is short enough for a piece of 1x2 or similar board that will used to secure the duct to. The flush end will be capped off and the end with the price of wood will be open and connect to duct from the fan. Also make sure that the top of the filter box as well

As the “end cap piece” is cut to a width that will have the box sitting over the frame with just the slightest bit of wiggle room.

Here’s that end capped and piece of 1x2 on the open end.

Another view of where we’re at so far.

Last edited: