My room is 4.10'w x 9.10'L x 6.10' tall= 228 cubic'.

I want to exchange the air 2x a min.

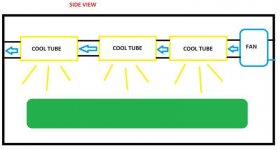

I have 3x 600Hps in 3 yield master II hoods being vented out using a 6" 400cfm fan.

I also have another 6" 400cfm fan venting the room.

My question is how much more air am I going to vent with the 3-600's?

Also how big do my intakes have to be? I got 2-6" holes all ready?

I want to exchange the air 2x a min.

I have 3x 600Hps in 3 yield master II hoods being vented out using a 6" 400cfm fan.

I also have another 6" 400cfm fan venting the room.

My question is how much more air am I going to vent with the 3-600's?

Also how big do my intakes have to be? I got 2-6" holes all ready?