I've got a cabinet that I made which is 20" deep 33" wide and 60" tall. I'm going to use a 400W HPS in a cool tube. I planned on using a separate smaller computer type fan just for the cool tube. And I want to get the S&P TD100x 4" inline rated at 135cfm for the rest of the cabinet vented through a 4" duct in the top. I was wondering if (8) 1" thin walled PVC pipe would be sufficient for the passive intake. I don't have a lot of room for the intake because I would like it to go through the bottom. I'll be doing an ebb & flow hydro setup and the tray will take up most of the bottom except for a couple inches around each side.

-

As of today ICMag has his own Discord server. In this Discord server you can chat, talk with eachother, listen to music, share stories and pictures...and much more. Join now and let's grow together! Join ICMag Discord here! More details in this thread here: here.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

400W cooltube cabinet airflow ?

- Thread starter jus.lor

- Start date

I've got a cabinet that I made which is 20" deep 33" wide and 60" tall. I'm going to use a 400W HPS in a cool tube. I planned on using a separate smaller computer type fan just for the cool tube. And I want to get the S&P TD100x 4" inline rated at 135cfm for the rest of the cabinet vented through a 4" duct in the top. I was wondering if (8) 1" thin walled PVC pipe would be sufficient for the passive intake. I don't have a lot of room for the intake because I would like it to go through the bottom. I'll be doing an ebb & flow hydro setup and the tray will take up most of the bottom except for a couple inches around each side.

I run a 400w in a similarly sized cabinet. Most people with this setup run one big fan with passive intakes. The air moves in the in through the passive intakes, then through the cooltube, and out the cab. I'm not sure about the in-line you selected. I run a 6" Vortex rated at 449cfm and it works pretty good. I think a 4" Vortex would also work in my situation, though probably not as well.

Pine

Well, the way I figure it is that I have about 24 cu ft. And 135cfm, in my opinion, is plenty of airflow to exchange the air inside the cabinet around 5 times a minute. I know it's not going to be that high exactly, but I think that would be sufficient even with some restrictions. I was just going with the S&P because I was trying to keep everything small to maximize my grow area, but most importantly....price. I just want to make sure that I'm not going to have any heat issues before I get too far into this.I run a 400w in a similarly sized cabinet. Most people with this setup run one big fan with passive intakes. The air moves in the in through the passive intakes, then through the cooltube, and out the cab. I'm not sure about the in-line you selected. I run a 6" Vortex rated at 449cfm and it works pretty good. I think a 4" Vortex would also work in my situation, though probably not as well.

Pine

supersoulbro1

New member

get a 6 in vortex or you will have heat problems check around 400 puts off nice heat

A 4" Vortex and a 4" S&P are two different things. The S&P can't compete with Vortex for pulling power. A 4" Vortex may work but my 4" S&P (at 100 cfm) is seriously taxed cooling my 250. I wouldn't want to recommend it for a 400.

A 4" fan would use Thirty-Two (32) 1" intakes. If you can't go through the bottom, go through the side as low as possible without being blocked. Make it easy on yourself, get a 4" hole saw (or whatever size fan you get), punch three holes and be done.

A 4" fan would use Thirty-Two (32) 1" intakes. If you can't go through the bottom, go through the side as low as possible without being blocked. Make it easy on yourself, get a 4" hole saw (or whatever size fan you get), punch three holes and be done.

Man, thanks for all the advice you guys.

The 4" vortex isn't too much more in regards to price, so I think I might take the advice and go with one. Better do it right the first time. I hope I don't have to scale down to a 250W to keep the temps under control, cuz I don't think that's enough light. I just want the most bang for my buck.

Now, with the intakes, I guess I'll have to figure something out. Cuz I don't have room for 32 damn PVC pipes. Maybe I'll get a darkroom vent and slap that on the back for some extra air. I don't know yet.

The 4" vortex isn't too much more in regards to price, so I think I might take the advice and go with one. Better do it right the first time. I hope I don't have to scale down to a 250W to keep the temps under control, cuz I don't think that's enough light. I just want the most bang for my buck.

Now, with the intakes, I guess I'll have to figure something out. Cuz I don't have room for 32 damn PVC pipes. Maybe I'll get a darkroom vent and slap that on the back for some extra air. I don't know yet.

Note a 4" Vortex is 11(?)" dia and screams like a banshee with a bullhorn. The 4" S&P is 5" dia. and considerably quieter.

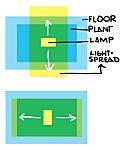

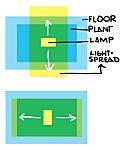

A 250 would be nearly ideal in your cab (mine has me buried alive) the only "problem" is the cab's lack of depth. Lamps throw little to no light forward or aft, and you've quite a spread. See if you can't get the lamp parallel to the short end of the grow. This allows you to hang the lamp lower with a larger effective footprint. Consider some sort of V or stadium type canopy control where the left and right edges are higher than the middle.

A 250 would be nearly ideal in your cab (mine has me buried alive) the only "problem" is the cab's lack of depth. Lamps throw little to no light forward or aft, and you've quite a spread. See if you can't get the lamp parallel to the short end of the grow. This allows you to hang the lamp lower with a larger effective footprint. Consider some sort of V or stadium type canopy control where the left and right edges are higher than the middle.

BLUNToPOTomuss

Member

Cooling a bulb only, a good ratio is .3cfm per watt

I'm thinking that I'm just going to downgrade to a 250W HPS. I don't want to have to worry about my temps like I would with a 400W. And I've been trying to figure out a way to mount my light like you're talking about FB, but my cooltube doesn't leave much room. If anything, I'll probably mount it diagonally.

For yor passive intakes and using a 4" inline centrifugal (Vortex,Elicent,Can Fan,EcoPlus,Hurricane Fans) you want your intake area to be atleast 3.3x the area of your exhuast fan so for a 4" exhuast fan we would want to have a minimum of 13.2 sq. inches of surface area.You can do eight 2" OD PVC pipes with 90 degree bends for light trapping or you can do one-two 8" x 8" darkroom louvers.

As far as lighting and you worrying about temps.....I live in Florida where it gets well above 90F for 8-9 months out of the year.As long as your ambient temps are low enough I would not worry.I use a 400w HPS in an A/C'd hood in a C-13 (2' x 2.5' x 5.5' / 27.5 cubic feet) and I both air cool my light and exhuast (supply fresh air) the cab with just one 4" 172cfm EcoPlus inline centrifugal exhuast fan....with ambient temps at 72F my cab will run about 75-80F.

Visit the Ventilation 101 thread in my sig. lot's of great info there...and the How do I design a fan powered cooling system for my growbox FAQ also in my sig....and you might want to check out the old OG FAQ How Do I install an exhuast fan to operate most efficiently FAQ.

As far as lighting and you worrying about temps.....I live in Florida where it gets well above 90F for 8-9 months out of the year.As long as your ambient temps are low enough I would not worry.I use a 400w HPS in an A/C'd hood in a C-13 (2' x 2.5' x 5.5' / 27.5 cubic feet) and I both air cool my light and exhuast (supply fresh air) the cab with just one 4" 172cfm EcoPlus inline centrifugal exhuast fan....with ambient temps at 72F my cab will run about 75-80F.

Visit the Ventilation 101 thread in my sig. lot's of great info there...and the How do I design a fan powered cooling system for my growbox FAQ also in my sig....and you might want to check out the old OG FAQ How Do I install an exhuast fan to operate most efficiently FAQ.

A minimum intake area would be closer to 10% more intake than you have exhaust. A good rule of thumb is to have double the exhaust area in intake hole. Any more is really wasted work, as the fan cannot do anything with the increased opening.For yor passive intakes and using a 4" inline centrifugal (Vortex,Elicent,Can Fan,EcoPlus,Hurricane Fans) you want your intake area to be atleast 3.3x the area of your exhuast fan so for a 4" exhuast fan we would want to have a minimum of 13.2 sq. inches of surface area.You can do eight 2" OD PVC pipes with 90 degree bends for light trapping or you can do one-two 8" x 8" darkroom louvers.

If you have a fancy intake opening (iris valve) that would incrementally open at your adjustment, you would find that the fan...any fan...will reach it's CFM potential when the adjustable opening is just past the same size opening as the exhaust.

It's no big deal to have way more opening than needed, but work and space is a premium in most grows, and the extra hole (or 1.3 holes as it were) is simply not needed.

I was also wondering about what to make my door out of.

I know it's a little off subject, but I didn't want to start a thread on that.

I was looking for something that isn't going to warp...and if it does, not that much. But ultimately, I'm focused on price. It has to be about 34"W and 51"L. I was looking at OSB because it's cheap, but I was hoping there was something that would look better and still be cheap.

Any thoughts?

I know it's a little off subject, but I didn't want to start a thread on that.

I was looking for something that isn't going to warp...and if it does, not that much. But ultimately, I'm focused on price. It has to be about 34"W and 51"L. I was looking at OSB because it's cheap, but I was hoping there was something that would look better and still be cheap.

Any thoughts?

Last edited:

I've got the cabinet all put together now. I just have to get the light and fan inside pretty much. I'm just stuck on how to vent the cabinet out through my cooltube. I want to exhaust it through my utility room, but I don't know how to do it. I'm just looking for some ideas.

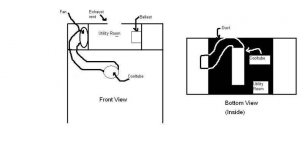

The pic I have is a half-assed attempt that I threw together on paint. I'm not really feeling like leaning how to use Google SketchUp. The left one is just basically a look from the front with what I would guess would be the easiest way. I want to try and mount my light parallel to the short wall.

The problem I have is that I want to exhaust it through the utility room and out the top. I want to make sure it blows air over the DIY ballast that I'm going to have in there to keep the temps down. So would it be very efficient to go cooltube>duct>fan>utility room and just have it blow into the utility room over the ballast and go out the vent? Or is there a better way to do it. I'm open to suggestions, cuz I don't really have any other ideas.

The pic I have is a half-assed attempt that I threw together on paint. I'm not really feeling like leaning how to use Google SketchUp. The left one is just basically a look from the front with what I would guess would be the easiest way. I want to try and mount my light parallel to the short wall.

The problem I have is that I want to exhaust it through the utility room and out the top. I want to make sure it blows air over the DIY ballast that I'm going to have in there to keep the temps down. So would it be very efficient to go cooltube>duct>fan>utility room and just have it blow into the utility room over the ballast and go out the vent? Or is there a better way to do it. I'm open to suggestions, cuz I don't really have any other ideas.

Attachments

You have neglected to deal with the issue of odor control. I'm assuming stealth is of some importance to you, since you are going to the trouble of putting your grow in a cab. You need to put a carbon filter on the end of your vent run.That's going to mess with your "blow air on the ballast" plans. Even with a carbon filter, there should still be a lot of air movement in the utility area, which will probably be enough to dissipate the heat from your ballast. Just keep an eye on the ballast temps when you first start to use it. It probably won't be necessary, but if the ballast gets too hot then you might have to drill a hole or two near it for ventilation or put a small fan on it, but you should see what it does without those first. (You could put your exhaust hole over the ballast. Then you know there would be airflow.)

PC

PC

You have neglected to deal with the issue of odor control. I'm assuming stealth is of some importance to you, since you are going to the trouble of putting your grow in a cab. You need to put a carbon filter on the end of your vent run.That's going to mess with your "blow air on the ballast" plans. Even with a carbon filter, there should still be a lot of air movement in the utility area, which will probably be enough to dissipate the heat from your ballast. Just keep an eye on the ballast temps when you first start to use it. It probably won't be necessary, but if the ballast gets too hot then you might have to drill a hole or two near it for ventilation or put a small fan on it, but you should see what it does without those first. (You could put your exhaust hole over the ballast. Then you know there would be airflow.)

PC

I haven't neglected how to deal with odor control. I've planned on using a carbon filter, that just wasn't part of my problem that I was having which is why I didn't mention it. I'm just more concerned with how to efficiently get the air into the utility room and cool off the ballast and exit the utility room. I don't want my fan just blowing hot air into the room and it just basically staying in there cuz it has nowhere to go. I'm just looking for some ideas to help me out cuz there's gotta be other ways to do it.

And isn't it more efficient to pull through a carbon scrubber than push through it?

I didn't mean to sound like I was dissing your cab, dude. I just looked at your drawings and didn't see a filter and thought you had forgot about one. Still. I think you should figure out a way for the air to flow around the ballast and that should keep it cool.enough. ...maybe some smaller holes in the top and sides near the ballast. I had two 400's in cooltubes, in a cab vented with a 6" Vortex. The air coming out the exhaust wasn't much more than warm. I had it arranged so that the air from the exhaust passed by the ballasts and everything always ran nice and cool.

It probably doesn't make a lot of difference to the air, but one big advantage to sucking vs blowing is that, if your flex line breaks, you are still sucking hot air from the cab. When blowing, if the flex line breaks you're just blowing hot air around in the cab. Been there, done that. Two weeks from harvest and everything was totally ruined. I thought I was using good quality flex line, but it broke anyway. If you can fit it in your box, the insulated flex ducting is much better quality (stronger) plus it keeps a little more heat out of your cab.

Now that I read your question again, carbon filters work both ways. In your case you want as much room as possible in your cab so you should put the filter on the end of the line. Looking at your drawing, you'll be lucky to get your light sideways, let alone put a filter on it.

Good luck with your project!

PC

It probably doesn't make a lot of difference to the air, but one big advantage to sucking vs blowing is that, if your flex line breaks, you are still sucking hot air from the cab. When blowing, if the flex line breaks you're just blowing hot air around in the cab. Been there, done that. Two weeks from harvest and everything was totally ruined. I thought I was using good quality flex line, but it broke anyway. If you can fit it in your box, the insulated flex ducting is much better quality (stronger) plus it keeps a little more heat out of your cab.

Now that I read your question again, carbon filters work both ways. In your case you want as much room as possible in your cab so you should put the filter on the end of the line. Looking at your drawing, you'll be lucky to get your light sideways, let alone put a filter on it.

Good luck with your project!

PC

I didn't mean to sound like I was dissing your cab, dude. I just looked at your drawings and didn't see a filter and thought you had forgot about one. Still. I think you should figure out a way for the air to flow around the ballast and that should keep it cool.enough. ...maybe some smaller holes in the top and sides near the ballast. I had two 400's in cooltubes, in a cab vented with a 6" Vortex. The air coming out the exhaust wasn't much more than warm. I had it arranged so that the air from the exhaust passed by the ballasts and everything always ran nice and cool.

It probably doesn't make a lot of difference to the air, but one big advantage to sucking vs blowing is that, if your flex line breaks, you are still sucking hot air from the cab. When blowing, if the flex line breaks you're just blowing hot air around in the cab. Been there, done that. Two weeks from harvest and everything was totally ruined. I thought I was using good quality flex line, but it broke anyway. If you can fit it in your box, the insulated flex ducting is much better quality (stronger) plus it keeps a little more heat out of your cab.

Now that I read your question again, carbon filters work both ways. In your case you want as much room as possible in your cab so you should put the filter on the end of the line. Looking at your drawing, you'll be lucky to get your light sideways, let alone put a filter on it.

Good luck with your project!

PC

I didn't mean to come off as defensive, I'm probably just not explaining it well enough. I put a pic of my cabinet here so maybe it'll make more sense. I appreciate the help though man.

This is how I originally was going to do it. And that's how I designed the cabinet. But, FreezerBoy had a good point about the light being positioned parallel to the short wall (I didn't even think about it). It would be much more efficient and I could put my light closer to the plants. I was just trying to see what's the best way to mount it that way. My problem is that I don't have a lot of depth (about 5" space between the cooltube and the walls).

Attachments

I think I'm just going to do it the way I have it in the picture. I was wondering if I get a S&P 100x if that would be enough to vent my cab if I'm going to use another fan for my cooltube (maybe a S&P 100 just for the cooltube). But if I have to step it up to the 125 for the exhaust then I will. I have a DIY scrubber that I'm in the process of building and I'm waiting to see what size fan I'm going to get before I finish the scrubber. The link to the scrubber is:

http://www.icmag.com/ic/showthread.php?p=509470

It looks like a good design. I already have all the parts, I just wanted some more advice on the fans before I get them. A Vortex is just too big and loud for my application.

Thanks you guys, you've already been a ton of help so far.

http://www.icmag.com/ic/showthread.php?p=509470

It looks like a good design. I already have all the parts, I just wanted some more advice on the fans before I get them. A Vortex is just too big and loud for my application.

Thanks you guys, you've already been a ton of help so far.