[Basic DIY Modifying a Lasko Blower for Cooling (part 1) = POST 19]

[Basic DIY Modifying a Lasko Blower for Cooling (part 2) = POST 20]

[A Friendly Tip On ODOR CONTROL = POST 27]

[SKIP TO SOME GREEN POST #28]

[plants got sick on POST 41]

[nursed back to health POST 89]

[WORLD CLASS CLONER NEW AT WALMART! 100% success rate EASY - CHEAP]

[PROOF IT WORKS]

[START OF BUDDAGE]

[HARVEST]

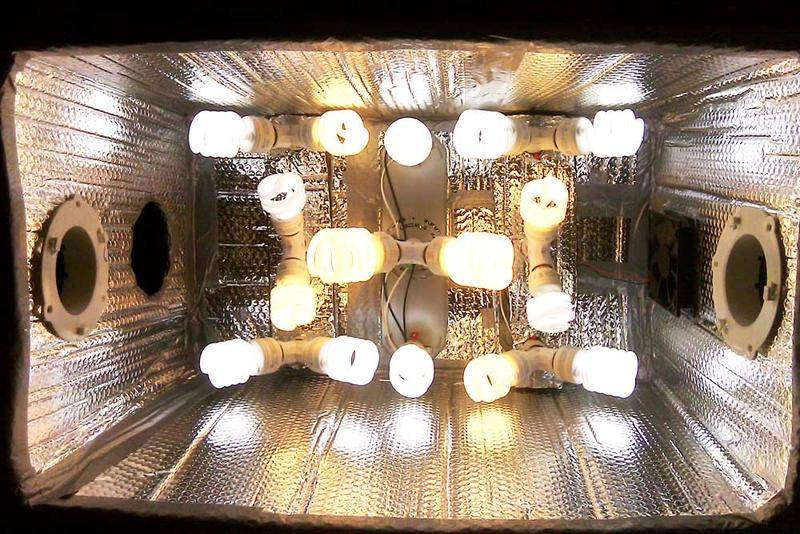

Hey everyone, I posted some of this info a wile back but I've decided to make and official "grow diary". Here's my 1st attempt at building a semi-stealth box and growing delicious fruit.

Let me start with my set-up

-I based my box on Red_Greenery's Rubbermaid Lodge

After finishing the box I started having instant heat problems because i based my exhaust system on red's 18 gal design while my box is 35gal.

I was using 122mm computer fan to cool 450 wats!

but now i just use the comp fans for inside the box.

I did some research and found a DIY blower fan to mod the box (i highly recommend it) and now my temps around 80F. I'll make a post on it later. (post #19 & #20 for the tut)

I put the unit under the house and made a 5'' hole through the closet floor for venting out the hot air and it works like magic.

-The first batch of seeds (lowrider), (after 1.5 months), never showed so i ordered from a more reliable place

(edit- the seeds finally showed up 4 months later LOL! WTH)

[Basic DIY Modifying a Lasko Blower for Cooling (part 2) = POST 20]

[A Friendly Tip On ODOR CONTROL = POST 27]

[SKIP TO SOME GREEN POST #28]

[plants got sick on POST 41]

[nursed back to health POST 89]

[WORLD CLASS CLONER NEW AT WALMART! 100% success rate EASY - CHEAP]

[PROOF IT WORKS]

[START OF BUDDAGE]

[HARVEST]

Hey everyone, I posted some of this info a wile back but I've decided to make and official "grow diary". Here's my 1st attempt at building a semi-stealth box and growing delicious fruit.

Let me start with my set-up

-I based my box on Red_Greenery's Rubbermaid Lodge

After finishing the box I started having instant heat problems because i based my exhaust system on red's 18 gal design while my box is 35gal.

I was using 122mm computer fan to cool 450 wats!

but now i just use the comp fans for inside the box.

I did some research and found a DIY blower fan to mod the box (i highly recommend it) and now my temps around 80F. I'll make a post on it later. (post #19 & #20 for the tut)

I put the unit under the house and made a 5'' hole through the closet floor for venting out the hot air and it works like magic.

-The first batch of seeds (lowrider), (after 1.5 months), never showed so i ordered from a more reliable place

(edit- the seeds finally showed up 4 months later LOL! WTH)