Pactivist

Active member

here is an easy and inexpensive way to make your own hash, it's how i've been doing it for a while and it works well, and can easily be adjusted to larger and smaller amounts of kif.

I try to use as much of my plants as is possible, and the trim used in this thread was intended for BHO, and is not the kind of trim I usually use for dry scuffing. what is left after scuffing will still go to BHO so still nothing is lost, but the final hash will be of slightly lower quality. better starting products yeilds a much better end product.

so here we go.

what you will need:

kif - i use dry scuffed (see below)

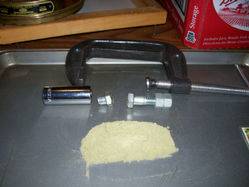

1 - deepwell socket (i use a 3/4")

2 - bolts which fit the socket tightly (more detail below)

2 - nuts which fit the the bolts

1 - large c-clamp

1 - smaller bolt or a drift punch to press the hash out

heat source (optional)

to make my kif i use a kitchen strainer, a cookie sheet, and a framed silkscreen 130 micron i think from a chain crafts store.

i grind the trim through the kitchen strainer

I then use a spoon to bounce the ground trim around for awhile, longer agitation usually leads to more plant matter in the kif

i collect up my kif

and repeat till all the trim is processed

now comes the fun part, one of the bolts will need to have the threads cut off, or will somehow have to fit into the socket upside down so that the head faces up (i used a dremel to cut the bolt down to size, hold it with vice grips if you choose to do this) the other bolt will need to have 2 nuts on the very end of it (see pic) tightened against each other (double nutted).

place the cut off (or otherwise modified) bolt into the socket upside down (head up)

add kif

press down as hard as you can with the head of the other bolt

keep adding kif until the socket is full and you can no longer compress it by hand, then put it in the c-clamp and tighten

i usually set it inside my gas oven (pilot light only) which keeps the temp around 88 degrees F, and every now and then i give it another twist just to keep the pressure on. i leave it like this for a minimum of 72 hours usually much longer. now it might be a little hard to get out, but i will post some tips on that when mine is ready to come out.

well that's about it for now - but here are a couple of things that i have found.

your source of kif really does not matter as long as the kif is dry,

to get the tightest fit between bolt and socket, i used a metric bolt sanded down to fit a 3/4" socket, also the longer it sits in the press - the easier the hash is to remove. one other thing - i need a good source for bulk silkscreen, to refine my kif further.

comments? suggestions? sources for silkscreen?

stay safe,

peAce,

pacT

I try to use as much of my plants as is possible, and the trim used in this thread was intended for BHO, and is not the kind of trim I usually use for dry scuffing. what is left after scuffing will still go to BHO so still nothing is lost, but the final hash will be of slightly lower quality. better starting products yeilds a much better end product.

so here we go.

what you will need:

kif - i use dry scuffed (see below)

1 - deepwell socket (i use a 3/4")

2 - bolts which fit the socket tightly (more detail below)

2 - nuts which fit the the bolts

1 - large c-clamp

1 - smaller bolt or a drift punch to press the hash out

heat source (optional)

to make my kif i use a kitchen strainer, a cookie sheet, and a framed silkscreen 130 micron i think from a chain crafts store.

i grind the trim through the kitchen strainer

I then use a spoon to bounce the ground trim around for awhile, longer agitation usually leads to more plant matter in the kif

i collect up my kif

and repeat till all the trim is processed

now comes the fun part, one of the bolts will need to have the threads cut off, or will somehow have to fit into the socket upside down so that the head faces up (i used a dremel to cut the bolt down to size, hold it with vice grips if you choose to do this) the other bolt will need to have 2 nuts on the very end of it (see pic) tightened against each other (double nutted).

place the cut off (or otherwise modified) bolt into the socket upside down (head up)

add kif

press down as hard as you can with the head of the other bolt

keep adding kif until the socket is full and you can no longer compress it by hand, then put it in the c-clamp and tighten

i usually set it inside my gas oven (pilot light only) which keeps the temp around 88 degrees F, and every now and then i give it another twist just to keep the pressure on. i leave it like this for a minimum of 72 hours usually much longer. now it might be a little hard to get out, but i will post some tips on that when mine is ready to come out.

well that's about it for now - but here are a couple of things that i have found.

your source of kif really does not matter as long as the kif is dry,

to get the tightest fit between bolt and socket, i used a metric bolt sanded down to fit a 3/4" socket, also the longer it sits in the press - the easier the hash is to remove. one other thing - i need a good source for bulk silkscreen, to refine my kif further.

comments? suggestions? sources for silkscreen?

stay safe,

peAce,

pacT

:friends:

:friends: