T

trem0lo

Hey all!

This is my second grow ever. My first was with JLP's Sour Diesel IBL and OG Kush cross (which I was lucky enough to receive) under 250w of HPS with excellent results. The resulting cross from a male and female of those seeds will be the subject of this grow.

Unfortunately my new house limits my grow space, and stealth is paramount. Enter the Quantum Tower LED PC case.

The Quantum Tower features a Lamptron fan controller with temperatures sensors and RPM control. It supports up to four 30w fans and temperature probes (F/C), and the RGB jumpers give nine color possibilities

I paired each fan with its own probe for temperature control and to calculate the CFM moving through the case and scrubber.

Temp/fan 1: Air intake temp

Temp/fan 2: Air exhaust temp

Temp/fan 3: Heatsink temp

Temp/fan 4: Canopy temp

My lighting source is 46w of Osram Golden Dragon Plus LEDs. Two separate strings are mounted to a 8x6 heatsink from an old thermoelectric cooler and are powered by two Meanwell LPC-35-700 drivers at 700mA. I used 15 660nm reds, 6 warm whites and 3 royal blues. The seedlings are loving it so far. Much thanks to KNNA for his LED expertise and help in choosing the proper light spectrum and building the lamp.

Open the case and you'll see that the design is relatively simple. I opted to not use a separate chamber for the electronics: Using the heat from the drivers and heatsink, the temps in the cabinet can be controlled from 5 to 15 degrees above ambient with the fan controllers, depending upon the season. I can also turn off one of the LED arrays via a front switch if things get too toasty in the summer. My intake and outtake fans are both Noctua NF-P12s and are rated for excellent static pressure as well as being completely silent. The grow space is approximately 17x18x8 inches.

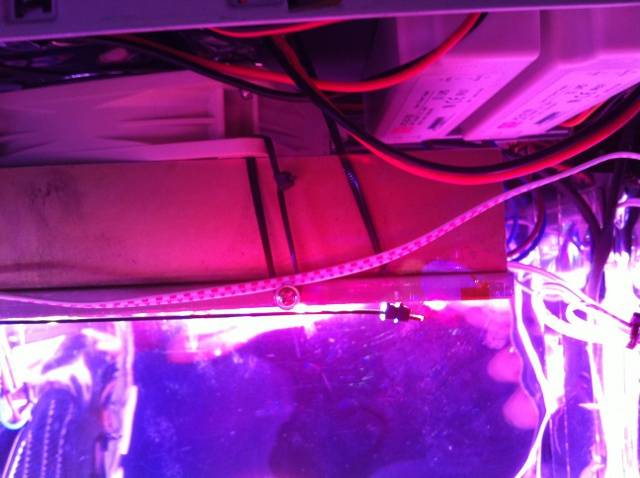

A closer look at the light. You can see the drivers mounted above it in the right top of the case with magnets. Another Noctua NF-P12 fan blows down on the heatsink to keep it warm to the touch. The wires run beside and above the heatsink to stay out of the grow space.

Thanks to everyone stopping in. I'll keep this thread updated as much as I can with pictures of the SDOG ladies and additions/improvements to the cab.

Peace!

This is my second grow ever. My first was with JLP's Sour Diesel IBL and OG Kush cross (which I was lucky enough to receive) under 250w of HPS with excellent results. The resulting cross from a male and female of those seeds will be the subject of this grow.

Unfortunately my new house limits my grow space, and stealth is paramount. Enter the Quantum Tower LED PC case.

The Quantum Tower features a Lamptron fan controller with temperatures sensors and RPM control. It supports up to four 30w fans and temperature probes (F/C), and the RGB jumpers give nine color possibilities

I paired each fan with its own probe for temperature control and to calculate the CFM moving through the case and scrubber.

Temp/fan 1: Air intake temp

Temp/fan 2: Air exhaust temp

Temp/fan 3: Heatsink temp

Temp/fan 4: Canopy temp

My lighting source is 46w of Osram Golden Dragon Plus LEDs. Two separate strings are mounted to a 8x6 heatsink from an old thermoelectric cooler and are powered by two Meanwell LPC-35-700 drivers at 700mA. I used 15 660nm reds, 6 warm whites and 3 royal blues. The seedlings are loving it so far. Much thanks to KNNA for his LED expertise and help in choosing the proper light spectrum and building the lamp.

Open the case and you'll see that the design is relatively simple. I opted to not use a separate chamber for the electronics: Using the heat from the drivers and heatsink, the temps in the cabinet can be controlled from 5 to 15 degrees above ambient with the fan controllers, depending upon the season. I can also turn off one of the LED arrays via a front switch if things get too toasty in the summer. My intake and outtake fans are both Noctua NF-P12s and are rated for excellent static pressure as well as being completely silent. The grow space is approximately 17x18x8 inches.

A closer look at the light. You can see the drivers mounted above it in the right top of the case with magnets. Another Noctua NF-P12 fan blows down on the heatsink to keep it warm to the touch. The wires run beside and above the heatsink to stay out of the grow space.

Thanks to everyone stopping in. I'll keep this thread updated as much as I can with pictures of the SDOG ladies and additions/improvements to the cab.

Peace!

Turns out my soldering skills were weak: I had multiple sites of bad (dull) solder sites. Simply reheating them so they adhered to the LED leads (rather than just covering them) did the trick. If the solder is shiny, it's a much better conductor. Use the multimeter (told you you'd need it) in diode mode to troubleshoot your connections. The LED will light up if it's good. Otherwise it's like a Christmas tree light string--If one connection is bad, the whole circuit won't work.

Turns out my soldering skills were weak: I had multiple sites of bad (dull) solder sites. Simply reheating them so they adhered to the LED leads (rather than just covering them) did the trick. If the solder is shiny, it's a much better conductor. Use the multimeter (told you you'd need it) in diode mode to troubleshoot your connections. The LED will light up if it's good. Otherwise it's like a Christmas tree light string--If one connection is bad, the whole circuit won't work.