DANGER! lease be wide awake and aware of the inherent dangers of electricity before starting to "play around" with it as it is mean and unforgiving and will viciously bite, perhaps even kill if not respected. IMB

lease be wide awake and aware of the inherent dangers of electricity before starting to "play around" with it as it is mean and unforgiving and will viciously bite, perhaps even kill if not respected. IMB

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Electricity can be an intimidating concept for many because of the potential danger.

You can virtually eliminate that danger with a little knowledge and proper safety practices.

However, regardless of how much knowledge you have, never become lax in dealing with an electrical system, or it can be deadly.

* Before beginning any electrical repair, shut off the power. Remove the fuse or trip the breaker for the circuit you will be working on in your service panel. Use a neon tester to be sure the power is off. If there is any doubt, you can remove the main fuse or trip the main breaker. Remember: Removing the main fuse or tripping the main breaker will usually shut off the power to the entire house.

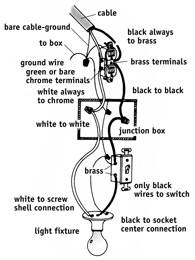

* Electrical wires are color coded to prevent wiring errors.

* White wires almost always connect to other white wires or to chrome terminal screws on switches and receptacles.

* Some wiring devices–such as receptacles–are back-wired by pushing the bare wire end into spring grip holes. These wiring devices are plainly labeled to show which color goes into each spring grip hole.

* Switches are nearly always connected into black wires in cables. The only exception is where a cable is extended, making it necessary for the white wire to play the role of the black wire. When this is necessary, the white wires should be painted black to prevent future wiring errors.

* Study the wiring diagram.

This will help you understand the basic principles of good wiring.

Also, find a good electrical how-to book.

It's one book every homeowner should keep on hand for ready reference.

* Most home wiring is complete with either No. 14 gauge or No. 12 gauge wiring. No. 14 is the smallest wiring permitted under most codes.

* Always use the same size cable for a continuation of any extended wiring circuit.

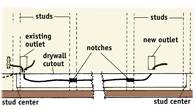

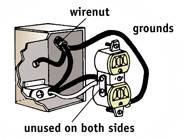

CONNECT NEW WIRING TO LAST OUTLET IN CABLE

* New wiring should be connected to the last outlet in a run of cable. To locate the last outlet in the run, shut off the current. Remove the cover plates from each outlet on the circuit. The last outlet in the run has wires connected to only two of the four terminal screws.

* The two unused terminal screws on the last receptacle serve as a starting point for wiring to a new outlet.

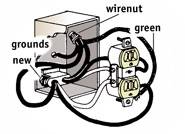

ATTACHING CABLE FOR NEW WIRING

* Shut off the power to the circuit you will be working on at the service panel.

* Loosen the screws holding the receptacle in the box and remove it.

* Attach the white wire to the chrome terminal, the black wire to the brass terminal on the receptacle and to the box, if the box is metal.

* Use care to match the size of the original cable. If No. 12 wire is used, continue with No. 12. If No. 14 wire is used, use No. 14 for continuing the cable. The size of the cable is usually stamped on the side of the cable.

* New wiring can be connected to continue the run beyond the last receptacle . Note that the new wires are pulled through knockout plugs in the back of the outlet box.

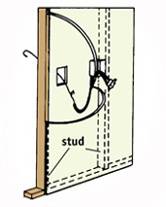

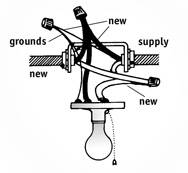

ADDING NEW WIRING FROM A JUNCTION BOX

* New wiring can also be tied into a junction box, unless the wiring in the junction box is already at maximum capacity.

* Before tying in at a junction box, always trace the cables leading to the box to check the voltage. Be sure you are not connecting a 120-volt outlet to a run of wire providing 240 volts for larger appliances.

* To tie in new wiring at a junction box, first shut off the current at the service panel.

* Locate the main supply cable coming into the junction box from the service panel. Locate the supply wire by tracing the white wires. All white wires in the junction box will be attached to the white wire on the supply line

* Knock out the unused plug on the junction box and run the new line from the box as illustrated.

Be sure to use a cable clamp to secure the cable to the junction box.

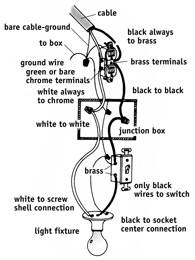

TYING IN NEW WIRING AT A CEILING LIGHT

* You can tie in new wiring at a ceiling light if the light is not controlled by a switch.

* Shut off the current at the service panel.

* Tie white wires to white wires and black wires to black wires..

* Connect the ground wires as illustrated. If you are using a metal box, attach them to the box as well as the light fixture.

* Knock out an opening in the outlet box, and continue the new wiring as illustrated.

>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>>

Electricity can be an intimidating concept for many because of the potential danger.

You can virtually eliminate that danger with a little knowledge and proper safety practices.

However, regardless of how much knowledge you have, never become lax in dealing with an electrical system, or it can be deadly.

* Before beginning any electrical repair, shut off the power. Remove the fuse or trip the breaker for the circuit you will be working on in your service panel. Use a neon tester to be sure the power is off. If there is any doubt, you can remove the main fuse or trip the main breaker. Remember: Removing the main fuse or tripping the main breaker will usually shut off the power to the entire house.

* Electrical wires are color coded to prevent wiring errors.

* White wires almost always connect to other white wires or to chrome terminal screws on switches and receptacles.

* Some wiring devices–such as receptacles–are back-wired by pushing the bare wire end into spring grip holes. These wiring devices are plainly labeled to show which color goes into each spring grip hole.

* Switches are nearly always connected into black wires in cables. The only exception is where a cable is extended, making it necessary for the white wire to play the role of the black wire. When this is necessary, the white wires should be painted black to prevent future wiring errors.

* Study the wiring diagram.

This will help you understand the basic principles of good wiring.

Also, find a good electrical how-to book.

It's one book every homeowner should keep on hand for ready reference.

* Most home wiring is complete with either No. 14 gauge or No. 12 gauge wiring. No. 14 is the smallest wiring permitted under most codes.

* Always use the same size cable for a continuation of any extended wiring circuit.

CONNECT NEW WIRING TO LAST OUTLET IN CABLE

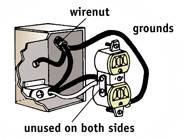

* New wiring should be connected to the last outlet in a run of cable. To locate the last outlet in the run, shut off the current. Remove the cover plates from each outlet on the circuit. The last outlet in the run has wires connected to only two of the four terminal screws.

* The two unused terminal screws on the last receptacle serve as a starting point for wiring to a new outlet.

ATTACHING CABLE FOR NEW WIRING

* Shut off the power to the circuit you will be working on at the service panel.

* Loosen the screws holding the receptacle in the box and remove it.

* Attach the white wire to the chrome terminal, the black wire to the brass terminal on the receptacle and to the box, if the box is metal.

* Use care to match the size of the original cable. If No. 12 wire is used, continue with No. 12. If No. 14 wire is used, use No. 14 for continuing the cable. The size of the cable is usually stamped on the side of the cable.

* New wiring can be connected to continue the run beyond the last receptacle . Note that the new wires are pulled through knockout plugs in the back of the outlet box.

ADDING NEW WIRING FROM A JUNCTION BOX

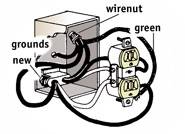

* New wiring can also be tied into a junction box, unless the wiring in the junction box is already at maximum capacity.

* Before tying in at a junction box, always trace the cables leading to the box to check the voltage. Be sure you are not connecting a 120-volt outlet to a run of wire providing 240 volts for larger appliances.

* To tie in new wiring at a junction box, first shut off the current at the service panel.

* Locate the main supply cable coming into the junction box from the service panel. Locate the supply wire by tracing the white wires. All white wires in the junction box will be attached to the white wire on the supply line

* Knock out the unused plug on the junction box and run the new line from the box as illustrated.

Be sure to use a cable clamp to secure the cable to the junction box.

TYING IN NEW WIRING AT A CEILING LIGHT

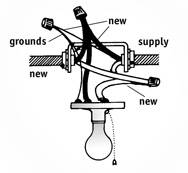

* You can tie in new wiring at a ceiling light if the light is not controlled by a switch.

* Shut off the current at the service panel.

* Tie white wires to white wires and black wires to black wires..

* Connect the ground wires as illustrated. If you are using a metal box, attach them to the box as well as the light fixture.

* Knock out an opening in the outlet box, and continue the new wiring as illustrated.

Last edited: