K

kelimmo

Hi fellow hobby growers.

I came across a problem while building a cabinet a while ago when the owner of the cabinet wasn't willing to let me drill big exhaust/intake holes for ventilation equipment.

I heard about some people who had built AC:s (or heat pumps for heating small sheds and equal) out of cheapo dehumidifier internals.

I had bought one for a larger growroom once and don't need it anymore so I thought I'd take it apart and look how its built up.

The design is really simple. Its built exactly like a portable AC only with smaller parts and the condenser and vaporizer aren't separated and equipped with a fan each.

This is what I started with

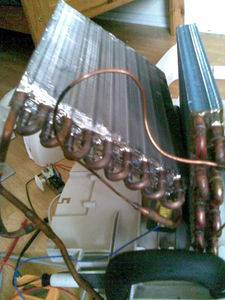

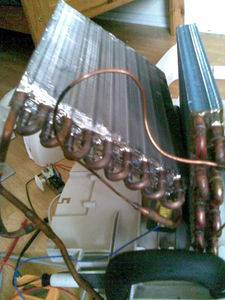

With just the front and back covers removed it looks like this:

I removed the fand and fan cover to get a better look at the heatsinks.

I'm replacing the hygrostat that was mounted on the front cover with a digital day/night thermostat.

The slightly bluish one is the one that gets cold if you don't want to test which one gets cold yourself.

if you don't want to test which one gets cold yourself.

CAREFULLY bending the warm side upward will help me place it on top of the upper shelf keeping the cold side and compressor inside the grow area.

This is what my test rig looks like right now:

Equipped with 4x120mm 12V fans it holds the cabinet equipped with a 210W Lohius CFL bulb at around 10F lower than room temperature!

I'll test it out with a 400w HPS when I'm done testing this setup.

So it's still just a PROOF OF CONCEPT but it has crazy potential. And no, I did't need to empty the system or use any tools but a copper pipe bender and a screwdriver.

The next thing to do is to remove the rest of the plastic housing and make small ducts for the fans. This will make the performance and size optimal and usable.

I came across a problem while building a cabinet a while ago when the owner of the cabinet wasn't willing to let me drill big exhaust/intake holes for ventilation equipment.

I heard about some people who had built AC:s (or heat pumps for heating small sheds and equal) out of cheapo dehumidifier internals.

I had bought one for a larger growroom once and don't need it anymore so I thought I'd take it apart and look how its built up.

The design is really simple. Its built exactly like a portable AC only with smaller parts and the condenser and vaporizer aren't separated and equipped with a fan each.

This is what I started with

With just the front and back covers removed it looks like this:

I removed the fand and fan cover to get a better look at the heatsinks.

I'm replacing the hygrostat that was mounted on the front cover with a digital day/night thermostat.

The slightly bluish one is the one that gets cold

CAREFULLY bending the warm side upward will help me place it on top of the upper shelf keeping the cold side and compressor inside the grow area.

This is what my test rig looks like right now:

Equipped with 4x120mm 12V fans it holds the cabinet equipped with a 210W Lohius CFL bulb at around 10F lower than room temperature!

I'll test it out with a 400w HPS when I'm done testing this setup.

So it's still just a PROOF OF CONCEPT but it has crazy potential. And no, I did't need to empty the system or use any tools but a copper pipe bender and a screwdriver.

The next thing to do is to remove the rest of the plastic housing and make small ducts for the fans. This will make the performance and size optimal and usable.

Last edited: