-

ICMag with help from Landrace Warden and The Vault is running a NEW contest in November! You can check it here. Prizes are seeds & forum premium access. Come join in!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

supercritical c02 extraction

- Thread starter smurfin'herb

- Start date

boroboro

Member

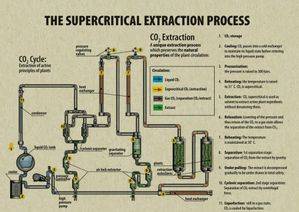

I'm a fan of extractions, and would certainly like to see this happen. Where did you get this diagram? I think I've seen (legal) herbal supplements made using this process.

The thing that jumps out at me is the pressure indicated: 300 bars for about half of the system, including the chamber the weed is in. That's about a metric buttload of pressure. Natural gas powered cars I used to work on had about 200-250 bars of pressure. Steel lines, valves, and fittings were readily available through suppliers like Mcmaster-Carr. Tanks and big chambers exist, but not inexpensively at those pressures.

I wouldn't build it myself, though, because of the pressures involved. Don't want to make a mistake with 4500 psi. Ouch.

I don't know these companies, but it looks like plenty of people would sell you a complete functional unit:

http://www.accudyne.com/b12_supercritical.html

http://www.supercriticalfluids.com/sft100xw.htm

http://www.edenlabs.org/supercritical_extraction.html

The thing that jumps out at me is the pressure indicated: 300 bars for about half of the system, including the chamber the weed is in. That's about a metric buttload of pressure. Natural gas powered cars I used to work on had about 200-250 bars of pressure. Steel lines, valves, and fittings were readily available through suppliers like Mcmaster-Carr. Tanks and big chambers exist, but not inexpensively at those pressures.

I wouldn't build it myself, though, because of the pressures involved. Don't want to make a mistake with 4500 psi. Ouch.

I don't know these companies, but it looks like plenty of people would sell you a complete functional unit:

http://www.accudyne.com/b12_supercritical.html

http://www.supercriticalfluids.com/sft100xw.htm

http://www.edenlabs.org/supercritical_extraction.html

JiggabooJones

Member

the edenlabs link looks like your best bet. Find out what the smallest consumer unit would cost.

Last edited:

EasyBakeIndica

Member

You can find these at some academic research laboratories

not gonna lie smurf, that looks like a waste of money when you can easily buy a shitton of cheap organic solvent and just build a giant evap area. care to explain why you wanna do this over a little more conventional/cheap methods? here's a list of a bunch of organic solvents if you care

http://organicdivision.org/organic_solvents.html

http://organicdivision.org/organic_solvents.html

as a rule of thumb the extraction of marihuana with carbon dioxide of density 0.9 g/ml at 40 degrees C for 34 min and of hashish for 18 min can be suggested. The application of the proposed extraction times ensured at least a 95% recovery for the main neutral cannabinoids.

Walter White - I would like to explore this a bit more for sure.

Here's a patent...

http://www.patentstorm.us/patents/7344736/description.html

In PCT/GB02/00620 the applicant discloses a method of preparing a herbal drug extract (botanical drug substance) from medicinal cannabis. The process comprises: 1. a heating step to decarboxylate the acid form of the cannabinoids to theirneutral form; 2. a first extraction with a specified volume of liquid carbon dioxide for 6 8 hours; and 3. a step to reduce the proportion of non-target materials, referred to as winterisation, which step precipitates out waxes.

More specifically, PCT/GB02/00620 describes a process wherein: step 1 comprises heating chopped cannabis (2 3 mm) at 100 150° C. for sufficient time to allow decarboxylation; step 2 comprises CO2 extraction using: a) a coarse powder(the particles are passed through a 3 mm mesh); b) a packing density of 0.3; and c) supercritical conditions of 600 bar at 35° C. for 4 hours, although other combinations of temp and pressure ranging from 10 35° C. and 60 600 bar (bothsuper critical and sub critical conditions) could, it is acknowledged, be used; and step 3 comprises conducting an ethanolic precipitation at -20° C. for 24 hours and removing the waxy material by filtration.

The supercritical method disclosed in PCT/GB02/00620 produced: a) a high THC extract containing: 60% THC (Δ9-tetrahydrocannabinol) 1 2% CBD (cannabidiol) 4 5% other minor cannabinoids including CBN (cannabinol) (Quantative yields were9% wt/wt based on dry weight of medicinal cannabis); and b) a high CBD extract containing: 60% CBD 4% THC 2% other cannabinoids (Quantative yields were 9% wt/wt based on dry weight of medicinal cannabis).

Clearly as the resulting BDS is to be used in a pharmaceutical product it is essential that the process is safe, scalable to GMP and gives high degrees of product consistency and, preferably also good yields.

The principles of supercritical fluid extraction (SFE) have been known since the work of Baron Cagniard de le Tour in 1822 when it was noted that the gas-liquid boundary disappeared when the temperature of certain materials was increased byheating them in a closed glass container. From this early work the critical point of a substance was first discovered. The critical point is the temperature above which a substance can co-exist in gas, liquid and solid phases. It was later found thatby taking substances to or above their critical temperature and pressure they could be used as sophisticated solvents for extraction and fractionation of complex mixtures.

People have been talking about supercritical fluid extraction of essential oils of cannabis online since OG's dawn and before I imagine. I can only personally attest to the talk at OG but perhaps others remember when butane extraction was referred to as supercritical fluid extraction. The Lycaeum and its ilk may have been responsible; I believe supercritical fluid extraction was the name given to the first successful butane extraction of DMT performed at the DMT Vaults in the fall of 1998.

What I have yet to see is anyone posting the results of a true supercritical extraction. To claim that there's no reason to pursue this as the above poster does is willful ignorance. There's no point in informing someone as to why CO2 and organic solvents might be slightly different to inhale at high temperatures should complete evaporation of solvent prove impractical if the person clearly thinks that CO2 and all organic solvents on that list are equally kosher to put in your resin.

Alright look at the last section of the last link posted at the top here. Because it is extremely awesome and will blow everyone's mind I will post a portion here below.

Looks like Eden Labs is violating INDRA's patent huh.

i can attest to this! the flame wars were massive, if we dont respect this they would have been flamed for nothing!

but seriously, there are people still looking into this, im sure foaf will be the first one to figure out how to do it on your own if it ever becomes possible. to be honest it would be thousands of dollars for each unit regardless of where you get it, is anyone wiling to invest 10K+? doubt it. if you are, buy a commercial unit! jeez, sometimes it dangerous as fuck to do somethings and sometimes regular laypeople shouldnt have access to dangerous as fuck things. im not talking like chainsaw or table saw or like hunting rifle. i mean more like a grenade which you cant find the pin to, and when you do, you find that it wont fit, so you have custom mill a new one, also the grenade is balancing on a pin in a vacuum sealed dome surrounded by landmines.

sooooo......be grateful your mind/body can grasp the butane process and complete that without(hopefully) blowing yourself up, some of you have stories im sure, i know i do. why cant people just be happy with what they have?

BHO is the top already.

Sundance

member

Any thoughts on these Home Herb Extraction Systems

http://www.edenlabs.org

More specifically

The Home Unit ... or ... The Apothecarian

http://www.edenlabs.org/home_light_commercial.html

Thanks

Sundance

http://www.edenlabs.org

More specifically

The Home Unit ... or ... The Apothecarian

http://www.edenlabs.org/home_light_commercial.html

Thanks

Sundance

More than that, I'm grateful you've taken the time to inform me of the error of my ways and to remind me to be grateful that my feeble mind can understand current methods. Now I can stop trying to improve my product and can rest assured that things are as good as they're going to get.

your very very welcome, someone has to inform you of your limits!

listen to HMK, he knows what hes talking about.

if youd spend thousands on a home extractor try one of these extractors,

http://tamisiumextractors.com/

they wont kill you as easily.

if you just want to be the first kid on the block to have co2 extraction, you should squash that.

if you havent witnessed a flame war over something as silly as super critical extraction then your lucky. there is already consensus on this topic, there has been for years, even bubbleman was in on some of those threads back in the OG days.

It's a good thing you don't want to start a flame war over anything silly. You're a fucking bitch, I bet your oil gets about as hard as your dick.

i tink he's right, your wasting your time....

BHO has tested at 98-99% THC according to Cannabis Culture and PAul Hornby, so why not just fucx with that and leave the co2 for the plants to breathe

Found this. Even though it is for catnip, I think it is interesting to hear what the steps are w/ a commercial device.

Oil of catnip was extracted via the supercritical fluid carbon dioxide in an

SFT1000 Supercritical Fluid Processing Unit (SFPU). The dried catnip (consisting of

Page 4 leaves, stems, and buds) was crushed and 17.533g were packed into a 50mL stainless steel vessel. After securing the vessel into place, the SFPU was set to the appropriate conditions. The conditions were checked using the “system status” function, and conditions were altered using the “rest parameter editor” function. The initial

temperature for the SFE/SFR was set to 40°C while the initial pressure setpoint was

2000 psi. During this time, the vessel filled with liquid carbon dioxide. The pressure was

raised in increments of 2000 psi by use of a pneumatic pump until the desired pressure

of 6000 psi was obtained. The SFPU operated in the static mode for 30 minutes

allowing the carbon dioxide time to soak through the catnip. After this time, the unit was

set to dynamic mode for 7 minutes, and the restrictor valve was opened manually 13 full

turns (completely opened is 17 turns) in the counter clockwise direction. It was

important to monitor the restrictor valve temperature at this time using the “system

status” function. If the temperature, set to approximately 60°C, fell below 5°C, the

restrictor valve had to be turned in the clockwise direction to maintain the temperature

above the freezing point. During this time, supercritical carbon dioxide extracted the oil

from the sample and carried it to the collection jar. After the completion of the 7

minutes, the pressure setpoint was reset to zero using the “rest parameter editor.” (The

mode was still dynamic). The restrictor valve was turned in the counter clockwise

direction allowing a rapid fall in pressure. When the pressure fell below 1200 psi, the

“open depressurization valve” function was selected to provide the final rapid

depressurization.

You can also check out the patent for Sativex http://www.patentstorm.us/patents/7344736/fulltext.html which is a sophisticated professinal supercritical co2 cannabis extraction for the pharmaceutical industry, it also describes a decarboxylation process but don't think it says what temp or how long for, it's pretty vague to my eyes actually but it's there. Bet they're equipment is home made.

Where's your sense of humour clide? Would they be able to sell these machines to the general public if they were as dangerous as you say? Why should a man who smokes as much bho as I presume Mr White does not be able to explore better and possibly cheaper in the long run alternatives. In fact why is he not even allowed to talk about it?

Its all fun stoner McGuiver type talk, but without some clear benefit you arent gonna get someone like me, who has the money and the skills (chemistry degree, welding equipment, and balls to do it) , to do it.

So what's the potential benefit? It is obviously more dangerous by virtue of the pressure, more expensive, and technically more demanding. If it provided some benefit, then Im all for it, but I havent heard of one valid known benefit. I'm not afraid of complicated, expensive, or dangerous. Look at the complicated goofy ass contraptions I've built to improve my hash/pot smoking life so far.

98%, not likely in most cases and even if it was, I dont know that that is "good", shit, the dark "weak" oil I sometimes make from a longer steep or second run is still too strong for me to smoke much of. and you can change the characteristics by using other solvents and varying steep times. cheaper? no way. easier, no way. larger amounts, not likely, pressure vessels get much more expensive as they get larger.

Low pressure room temperature solvent extractions are generally safe, inexpensive, quick, and make a product that I can't imagine improving on much, at least not taste wise or potency wise.

Its an interesting discussion, but from a reality standpoint, it aint happenin round here any time soon, and with good reason.

So what's the potential benefit? It is obviously more dangerous by virtue of the pressure, more expensive, and technically more demanding. If it provided some benefit, then Im all for it, but I havent heard of one valid known benefit. I'm not afraid of complicated, expensive, or dangerous. Look at the complicated goofy ass contraptions I've built to improve my hash/pot smoking life so far.

98%, not likely in most cases and even if it was, I dont know that that is "good", shit, the dark "weak" oil I sometimes make from a longer steep or second run is still too strong for me to smoke much of. and you can change the characteristics by using other solvents and varying steep times. cheaper? no way. easier, no way. larger amounts, not likely, pressure vessels get much more expensive as they get larger.

Low pressure room temperature solvent extractions are generally safe, inexpensive, quick, and make a product that I can't imagine improving on much, at least not taste wise or potency wise.

Its an interesting discussion, but from a reality standpoint, it aint happenin round here any time soon, and with good reason.