It's HOT and my plants need AC!

I have seen several tutorials here and on other forums on how to construct an AC box. Some of the tutorials available seem to be lacking very important points. In fact, I know for certain that some of the AC box tutorials are completely wrong, and will do nothing but cause the user problems, money, and a potentially ruined grow.

From what I have seen, the biggest problem AC box builders face is not knowing how the AC unit actually functions. I think that if many growers were to fully understand what the AC unit does, and how it does it, they would not have any troubles in constructing their own box. They would also be able to easily recognize the tutorials out there that are completely hosed up and should be disregarded.

I have actually tried to offer up some help with some of these AC box tutorials, but it seems that ego often trumps common sense, and some of these hosed up tutorial authors do not want to admit that they are putting out bad info.

Constructive criticism seems unwanted, even when heavily warranted.

If any grower sees a fault with my tutorial in any shape, form, or fashion please do not hesitate to bring it up for discussion. I have thick skin and have learned that the ego is something best left in your back pocket.

With all that said, let me continue with my presentation....

For this tutorial I am going to assume that you have chosen the correct size AC unit to fit your grow. Many factors can come into play when sizing the AC unit, and there are several tutorials available that give great info on figuring out the proper BTU size of the AC unit.

I am using a small 5000 BTU unit for this tutorial, which is what I am using for my cabinet mini-grow. I will go into my specific unit later...

Although this thread is not to show you how to pick the proper unit, I do recommend that growers use a manual controls unit if possible. Digitally controlled units can fail to restart properly if the incoming main power is ever shut off or lost for any reason. Manual control units will simply start to function normal again once the incoming power is restored. This seems like a small item, but it could potentially mean the difference between a nice harvest and a cooked, wilted out patch of nothing.

Manual controls units also make it easy to control using timers, and digitals may not actually give you that option.

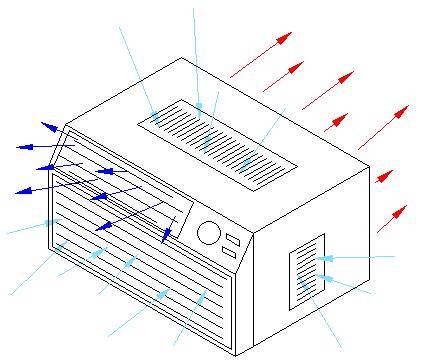

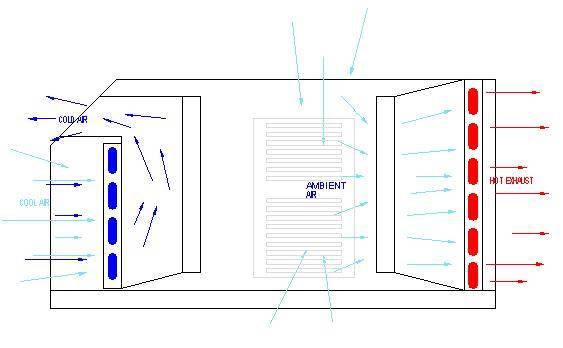

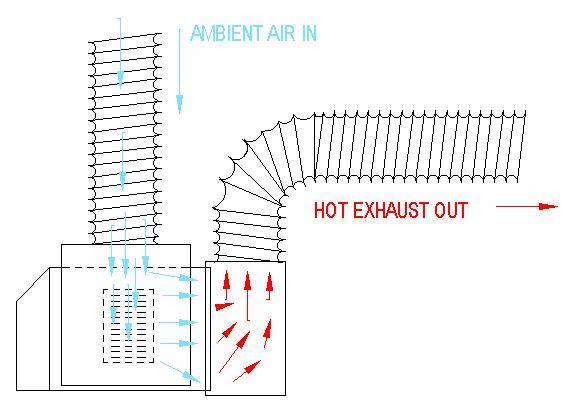

There is lots of air movement going on with an AC unit.

There are two main areas of an AC unit. The compressor side (cold side) and the condenser side (hot side).

These two area are separate from one another and have independent air flows. The cold side of the unit recirculates air that is within the grow space. This air is cooled by sucking it through the compressor coils and then returning it to the grow space. A thermostat on the front of the unit controls when the compressor will run and create more needed cold air.

The hot side of the unit uses ambient air that is not associated with the cooled space. This ambient air is sucked through the condenser coils, which cools the refrigerant material that flows inside of them. This hot air is then exhausted to the atmosphere.

There are options with how to configure your AC unit air flow.

The unit can be used in the conventional fashion by having a hole in the side of the grow room that allows just the cold side of the AC unit. The remainder of the unit (hot side) is outside of the grow area. This is similar to how the unit was designed to function. In fact, if you have a window in your grow room, you can mount just about any conventional AC unit without using a box at all, as that is how they are originally designed.

But having a widow in the grow room doesn't happen often. So we need to have other options.

One is to simply cut a hole in the grow room wall and only allow the cold side in the grow. The hot side can be in another room, and it can draw the ambient air needed to cool the hot side coils from that room. Although you must make certain that the room itself can draw in fresh air for the unit to use.

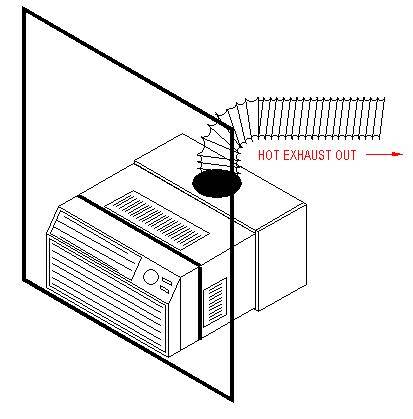

So far we have not constructed any box at all, but we will now need one for the hot side exhaust. We cannot let the hot exhaust go into our ambient air room, as it will quickly heat up the air in the room, which will eventually cause the AC unit to overheat and fail.

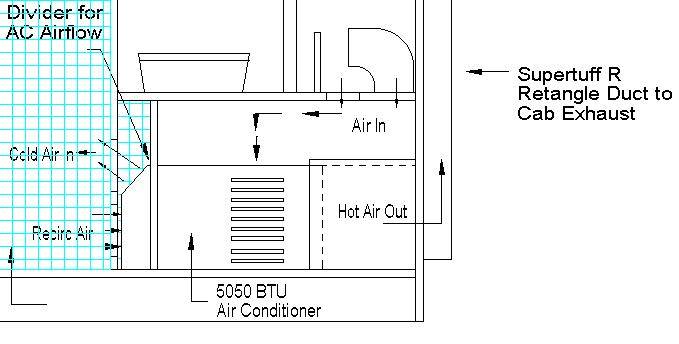

The box will need to enclose the whole back end of the AC unit, as the hot coils are nearly that size.

There is a fan on the inside of the AC unit that normally blows the ambient air from outside through the hot side coils and out to atmosphere. When we mount up a box around the exhaust of the unit, we must direct the air out somehow. For this, ductwork of some type is needed.

Sizing of this ductwork is of the utmost importance. The internal AC unit fan is blowing air at X amount of CFM through a fixed port size. Any time we restrict the size of the originally intended air flow, we jeopardize the integrity of the unit.

The vents in the side and top of the AC cover have provided adequate opening for the proper amount of ambient air to enter the unit. And as long as you do not choke down the air flow path downstream from the fan, then the unit will function properly.

If we kept the back end of our exhaust box open, and elongated the box until we reached an opening to the outside, then we would need no additional fans or ducting to exhaust the air properly. The problem is that this is often not a feasible thing to do.

So, we most often time depend on duct work that we add. The most common being 4" and 6" flexible ducting. Flexible ducting is one of the worst types of ducts we can use for air flow concerns, as that type of duct has a very large friction factor and can easily cut your airflow in half by simply making a turn.

Now, we can overcome the shortcomings of the smaller duct work by adding an additional fan that will assist with the air flow, or we can figure out what size duct we need to handle the air as normal.

One way to see if you have enough exhaust ducting is to take the AC unit cover off and measure the enclosure that surrounds the exhaust fan. This enclosure can be considered a duct, as it is the bottleneck of the AC unit's air flow. If your ducting is as large or larger than this enclosure around the fan, then you should be fine without an additional fan. But it is very seldom you will see folks running 10"-12" ductwork for AC boxes. Which is what even the smallest AC unit enclosure fan is going to be within.

OK, we have decided to use 6" flexible ducting and an additional fan to pull the air out of the box.

There is another option that can allow you to place your AC unit right inside of your grow room. However, we must do some work to make this happen. The ambient air that is used by the hot side to cool the coils should NOT be taken from the cool air grow room. This is a gross waste of energy and the cold air you spend money to create will simply be blown back out the exhaust. Eventually leaving you with a hot room and a failed AC unit. Not to mention that there is no oder control using this method, and the funk will find it's way out the exhaust.

What we need to do is to manipulate the incoming ambient air. To do this we construct another box around the ambient air vents, and duct this box to the outside so the unit can have fresh air.

You can build the box so that it completely encloses the intake air vents as in the previous sketch, and then run your duct to the outside.

You can also build a smaller box that only encloses one of the vents on the unit cover. The other incoming vents must be taped up and blocked off.

Thing is with this method is we run the risk of providing too little ambient air to the unit. If you choose to only duct in to one vent, make sure you snip the vent metal of the vent you are using so it opens it up. As long as you have the rectangular vent opening the same size or larger than your incoming duct, then it should be fine.

Again, if you have sufficient air flow area with your exhaust box, then you are going to also have to have sufficient air flow area with your incoming box as well...to get by without additional fans. However, since we normally will not have the correct size ducting, an additional fan is almost always warranted.

This additional fan can either be pushing on the intake side of things, or pulling from the exhaust side of things. Or both. The size of the ducting and fans are for another tutorial. Again, I am assuming you have these items worked out.

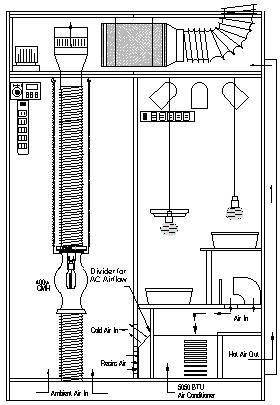

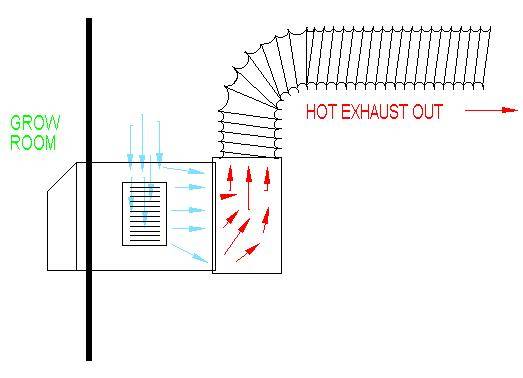

A free standing unit inside your grow room would look something like this:

If someone tries to convince you this will work, ask any HVAC man and see what he says. I guarantee it is a mistake to try it.

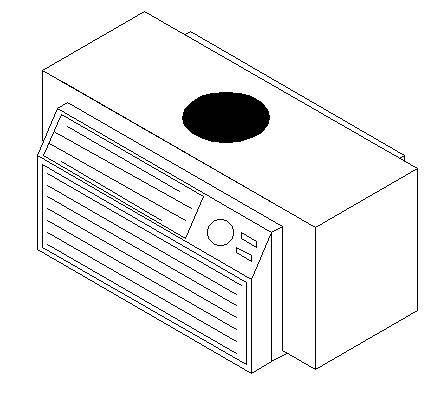

I realize that many simply do not have the tools or ability to build fancy boxes with wood. It can be a very daunting task for those who have never tried such work. But, there is an alternative.

I like to use aluminized foam insulation board. This stuff is very, very light weight, very easy to work with, and needs no special tools, save for a carpet knife, some duct or aluminum tape, and a ruler.

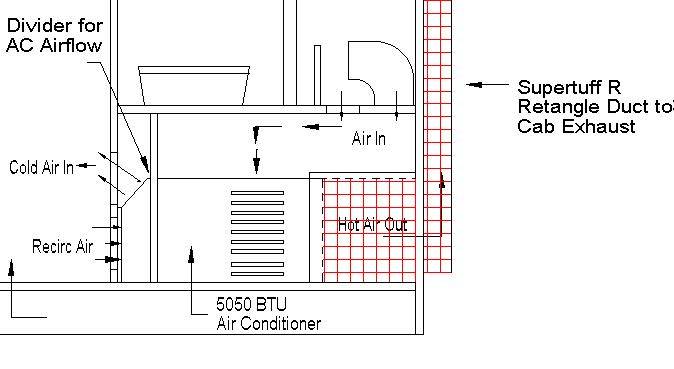

My product of choice is Dow Corning Supertuff R. This material is not only going to make it easy to build any sort of box you want in no time flat, it also is a great insulator and will not let the excess heat from the exhaust heat up the room. It also serves a decent sound barrier. Just remember to also wrap insulation around your flex duct if ambient heat is a concern.

Most AC units have a drain to get rid of the built up condensation that the condenser coils create when cooling them with the rush of air. You will need to compensate for the drain you have an run it to a safe runoff.

Some units are evaporative, and will not have a drain. These units will normally rely on the air movement to re-evaporate the condensed water back to the atmosphere. These types of units were designed to have the back end outside, and may not do what you think they will with the water. I suggest that you make a way to access the bottom of the inside of your unit so that you can periodically get the water out. I use a turkey baster to do this, and I have never had to take out more than an ounce of water or so from my evaporative unit. When the RH is low, the thing runs nearly bone dry.

I hope that this tutorial will be of help to fellow growers.

If you have any questions or concerns, please don't hesitate to post them up.

I will try my best to address any all questions. Or, I will try to get the right person involved that can clear up any cloudy issues for us.

Overgrow the world, and stay COOL!

Oh yeah...my AC unit!

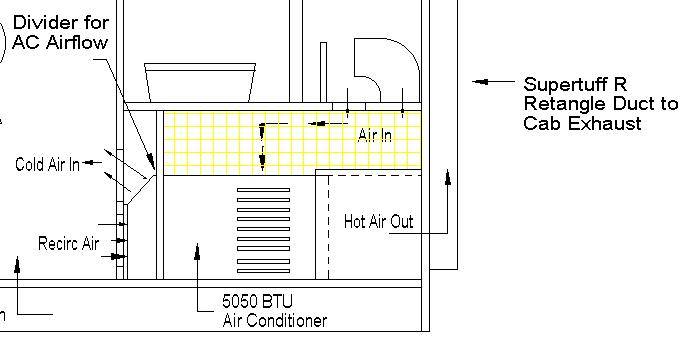

I have a 5050 BTU AC unit mounted inside my cabinet. The thing works like a charm and I have had no problems at all.

Air enters my veg chamber and flows through to the ambient air intake of the AC unit.

The ambient air is then run sucked through the hot side coils and exhausts the hot air out to duct work that leads to a DIY Stanley blower in the attic.

The cool side of my unit is in the flower area and is separated from the ambient and exhaust flows.