Quazi

Member

Hello everyone!

I'm getting close to the point of starting construction on my new cabinet so I figured it was time to start my own thread.

I originally posted some of these blueprints in the 150w HPS Club and Resource Guide and received some good feedback so far.

I am creating the cab to meet my needs as a patient so super-high yield isn't that important. In addition, I am complying with all state laws so stealth was not the biggest concern. The space I have is a large closet in my house. It doesn't get too hot where I live and the winters are long, so it seemed that the space would do.

The dimensions that I am working with are 4' tall, 3' wide and 2 feet or so deep.

After a lot of reading I found that the 150w HPS would be perfect for my needs so I decided to go with that. I also read that adding CFLs for spectrum can be helpful for the plants so I knew I wanted some accent lighting in the flowering room.

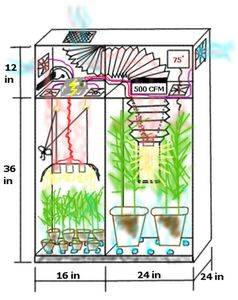

My first design was done using a paint program:

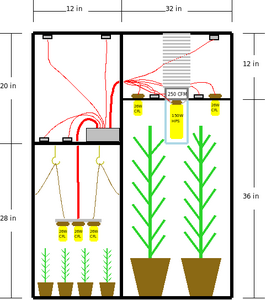

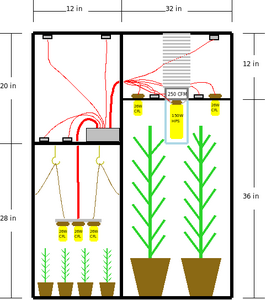

After conferring with my friends I found a cool open source program for the design, and came up with the second set of blueprints:

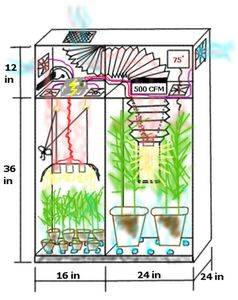

Now, after receiving some feedback from the folks in the 150w HPS Club, I have come to my third design:

The air intake for the cab will be through holes drilled in the bottom of the veg and flowering chamber. Both of the chambers will be lined with Mylar wrapping paper (or an equivalent). The veg chamber will have 3 26w CFLs on a bar that can be raised or lowered depending on the stage of the veg. There are two fans in the top of the veg chamber for ventilation. The flowering chamber will have a single 150w HPS lamp in the middle with a cool tube in the form of a straight 8" Hurricane glass shield. Additional ducting will be provided so the lamp can be raised or lowered. In addition, two 26w CFLs will be on either side of the flowering chamber with reflectors. This is for compliments to the spectrum. They will also be able to be raised or lowered. The small grey boxes around the electrical room are small fans.

I will be ordering my light next week so I plan to begin construction very soon.

This is my first attempt into the micro world so I am still looking for any kind of feedback before I begin construction. Please feel free to throw any suggestions my way!

Thanks!

I plan on taking lots of of the process/construction as well as the product so stay tuned!

of the process/construction as well as the product so stay tuned!

I'm getting close to the point of starting construction on my new cabinet so I figured it was time to start my own thread.

I originally posted some of these blueprints in the 150w HPS Club and Resource Guide and received some good feedback so far.

I am creating the cab to meet my needs as a patient so super-high yield isn't that important. In addition, I am complying with all state laws so stealth was not the biggest concern. The space I have is a large closet in my house. It doesn't get too hot where I live and the winters are long, so it seemed that the space would do.

The dimensions that I am working with are 4' tall, 3' wide and 2 feet or so deep.

After a lot of reading I found that the 150w HPS would be perfect for my needs so I decided to go with that. I also read that adding CFLs for spectrum can be helpful for the plants so I knew I wanted some accent lighting in the flowering room.

My first design was done using a paint program:

After conferring with my friends I found a cool open source program for the design, and came up with the second set of blueprints:

Now, after receiving some feedback from the folks in the 150w HPS Club, I have come to my third design:

The air intake for the cab will be through holes drilled in the bottom of the veg and flowering chamber. Both of the chambers will be lined with Mylar wrapping paper (or an equivalent). The veg chamber will have 3 26w CFLs on a bar that can be raised or lowered depending on the stage of the veg. There are two fans in the top of the veg chamber for ventilation. The flowering chamber will have a single 150w HPS lamp in the middle with a cool tube in the form of a straight 8" Hurricane glass shield. Additional ducting will be provided so the lamp can be raised or lowered. In addition, two 26w CFLs will be on either side of the flowering chamber with reflectors. This is for compliments to the spectrum. They will also be able to be raised or lowered. The small grey boxes around the electrical room are small fans.

I will be ordering my light next week so I plan to begin construction very soon.

This is my first attempt into the micro world so I am still looking for any kind of feedback before I begin construction. Please feel free to throw any suggestions my way!

Thanks!

I plan on taking lots of

of the process/construction as well as the product so stay tuned!

of the process/construction as well as the product so stay tuned!Quazi said:EDIT: scrapped the vertical design and the movable veg chamber lights. Ended up much more "NGBish" in style. Design ended up looking much closer to this:

The difference being that the CFLs are dropped vertically through the roof of the veg chamber with over-sized holes to allow air to flow over them. You'll have to check out the rest of the thread to see how it actually ended up.

Yes, it works:

Read on to find out more!

Last edited: